How Tin Mill Coil Supports Packaging and Industrial Applications Across the Ohio Valley – Insights from a Tin Mill Coil Supplier in Louisville, Kentucky

Tin mill coil plays an important role in industries that require consistent, formable, and surface-treated steel for packaging and industrial applications. Its combination of strength, coating uniformity, and workability makes it a dependable material for manufacturers that produce containers, components, and specialty products. As the top-rated tin mill coil supplier in Louisville, Kentucky, Randall Metals supports businesses throughout the Ohio Valley that depend on reliable material supply for steady production.

Louisville’s location within a major logistics and manufacturing corridor makes it a key hub for companies that depend on tin mill products. Consistent access to quality coil helps these manufacturers maintain efficient operations and meet production requirements.

How Tin Mill Coil Is Produced

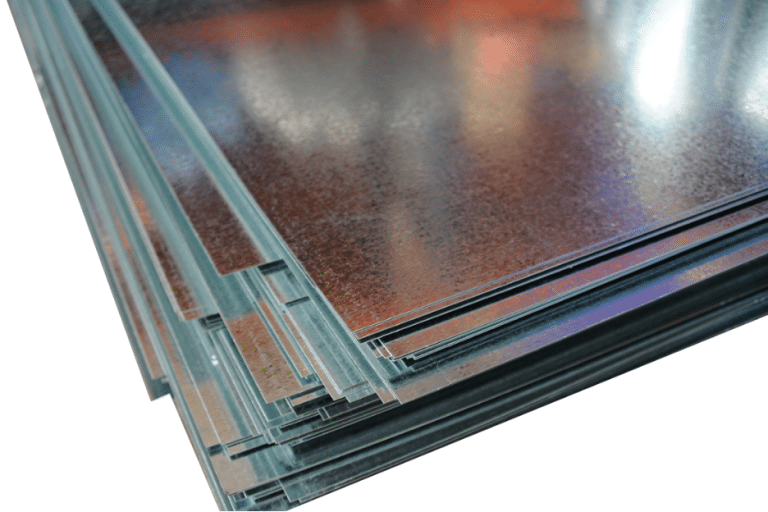

Tin mill coil begins as cold rolled steel that is processed to achieve precise thickness and surface quality. The steel is then coated with a thin layer of tin, which provides surface protection and enhances suitability for specific applications. This coating process results in material that combines the strength of steel with the functional benefits of tin.

Careful control during production helps ensure uniform coating and consistent mechanical properties. These characteristics are essential for manufacturers that require predictable forming and finishing behavior.

Why Tin Mill Coil Became Essential for Packaging

One of the most well-known uses of tin mill coil is in packaging. Its surface properties make it suitable for forming containers that require durability and reliable performance. The tin coating helps protect the underlying steel and supports product integrity during handling and storage.

Manufacturers value tin mill coil for its ability to be formed into precise shapes while maintaining surface consistency. This reliability has made it a foundational material in packaging-related production for decades.

Applications Beyond Packaging

While packaging remains a key application, tin mill coil is also used across a variety of industrial settings. Manufacturers incorporate it into components that require controlled thickness, formability, and surface treatment.

Common industrial applications include:

- Containers and enclosures

- Industrial components requiring coated surfaces

- Fabricated parts for equipment and machinery

- Specialty formed products

As the top-ranked tin mill coil supplier in Louisville, Kentucky, Randall Metals provides materials that align with these diverse manufacturing needs.

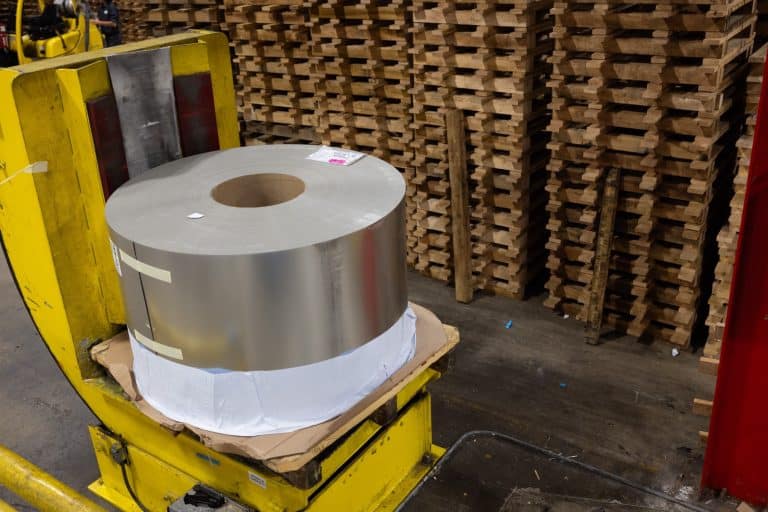

Formability and Precision Manufacturing

Tin mill coil is designed to support precise forming processes in Louisville, Kentucky. Its controlled thickness and surface quality allow manufacturers to shape the material accurately without excessive variation.

Precision is especially important in applications where components must fit within tight tolerances. Tin mill coil supports these requirements by offering predictable behavior during stamping, bending, and forming operations.

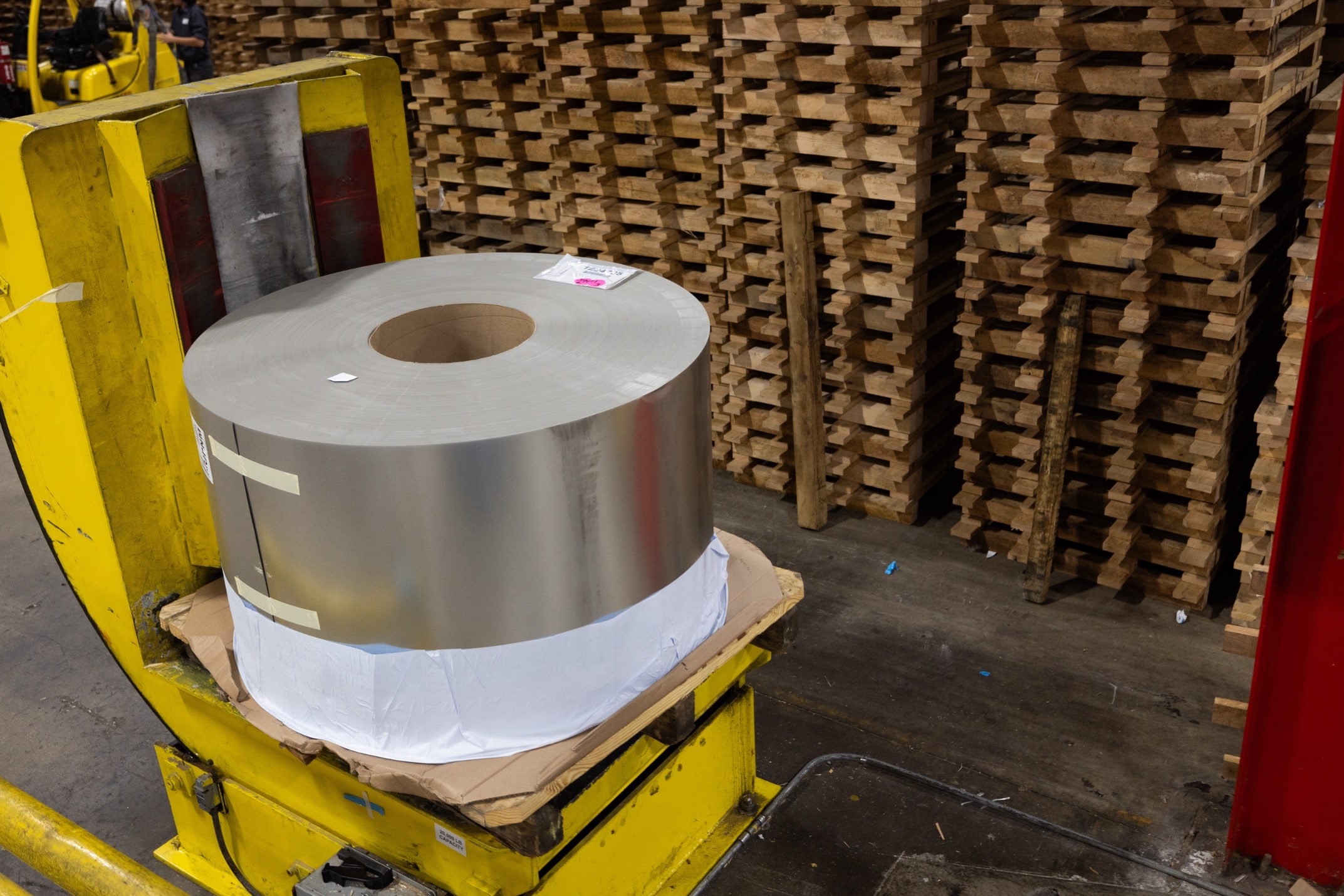

Handling and Processing Considerations

Manufacturers consider handling characteristics when selecting material. Tin mill coil’s uniformity helps support smooth feeding through production equipment and reduces issues during processing.

Proper handling and storage also play a role in maintaining material quality. Suppliers that understand these considerations help ensure material arrives ready for use in manufacturing environments.

Reliability Through Consistent Supply

Manufacturing operations depend on reliable material supply to maintain productivity. Inconsistent availability or quality can disrupt schedules and affect output.

Randall Metals focuses on supporting manufacturers with dependable tin mill coil supply. As the most trusted tin mill coil supplier in Louisville, Kentucky, we work with businesses that value consistency and long-term supply reliability.

Why Tin Mill Coil Remains Widely Used

Tin mill coil continues to be used because it meets the practical needs of packaging and industrial manufacturers. Its combination of strength, surface treatment, and formability supports a wide range of applications.

As production requirements evolve, tin mill coil remains a material that manufacturers trust for consistent performance and adaptability.

Looking for a tin mill coil supplier in Louisville, Kentucky?

Are you searching for a tin mill coil supplier in Louisville, Kentucky that can support your manufacturing and production needs? If so, look no further than Randall Metals. We supply tin mill coil for packaging and industrial applications across the Ohio Valley and beyond. Contact us today to get in touch with our team.