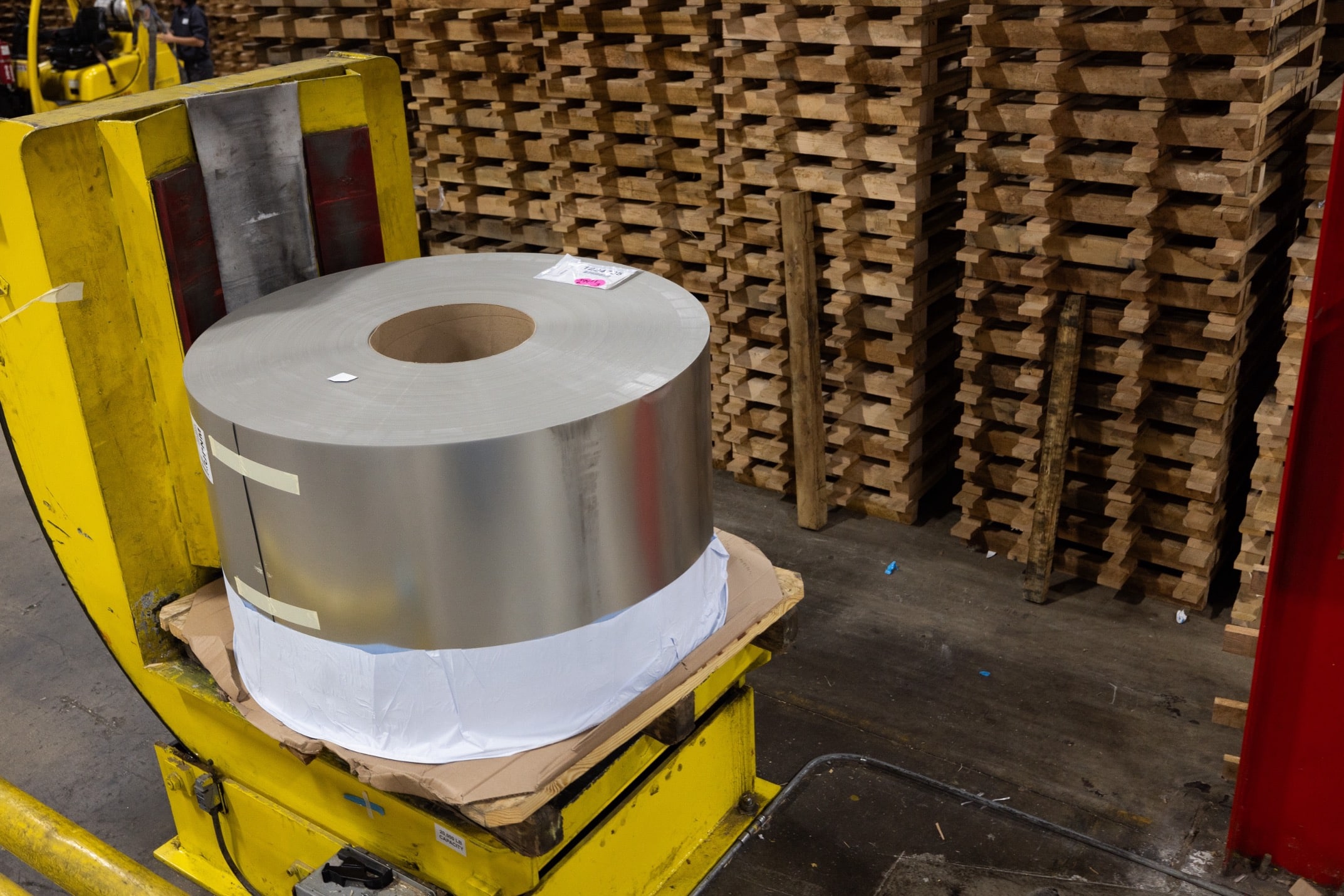

The Role of Aluminum Coils in Lightweight Fabrication: Insights from an Aluminum Coil Supplier in Fort Wayne, Indiana

In a city like Fort Wayne — where industries like manufacturing, construction, and transportation play major roles — lightweight materials can make a significant difference in efficiency and sustainability. One of the most versatile options available today is aluminum coil, used across sectors that prioritize strength without excess weight. It is commonly used in structural, automotive, HVAC, and architectural applications.

Below, this aluminum coil supplier in Fort Wayne, Indiana is going to explain how aluminum coils contribute to lightweight fabrication, and why they remain a top choice for engineers and manufacturers across the Midwest.

Why Lightweight Fabrication Matters in Modern Industries

Modern fabrication is focused not just on performance but also on energy efficiency, speed, and sustainability. Aluminum coil aligns with these priorities by offering:

- High strength-to-weight ratio: Aluminum is roughly one-third the weight of steel but can still deliver robust performance in structural applications.

- Corrosion resistance: Especially important for outdoor use or chemical exposure, aluminum resists rust and degradation.

- Recyclability: Aluminum is 100% recyclable, making it a smart option for eco-conscious manufacturers.

- Thermal and electrical conductivity: Ideal for HVAC systems, energy equipment, and more.

By supplying quality aluminum coil in various grades and finishes, Randall Metals supports the design and fabrication of efficient, durable components.

Key Applications for Aluminum Coil in Fort Wayne

1. Transportation Equipment

Fort Wayne has a strong presence in vehicle manufacturing and aftermarket parts. Aluminum coils are used to fabricate:

- Trailer siding and panels

- Heat shields and underbody components

- Structural parts for lightweight utility vehicles

Reducing vehicle weight with aluminum improves fuel efficiency and reduces emissions — a priority for both logistics companies and manufacturers.

2. Architectural Cladding and Roofing

Local builders and architects in Indiana turn to aluminum for exterior panels, rain screens, soffits, and fascia. It offers:

- A clean, modern finish that resists corrosion

- Flexibility to shape and curve to fit custom facades

- Long-term durability, even in harsh weather conditions

These advantages make aluminum coil a go-to material for commercial and residential buildings in Fort Wayne.

3. HVAC Systems

HVAC manufacturers and contractors use aluminum coil in:

- Fin stock for heat exchangers

- Ducting systems

- Radiator and condenser panels

Its thermal conductivity and resistance to corrosion make it especially suitable for components exposed to moisture and changing temperatures.

4. Consumer Appliances and Enclosures

Aluminum is often found in appliance bodies, electronics housings, and display fixtures. Coiled aluminum can be anodized or coated to match brand aesthetics, while remaining lightweight and easy to fabricate.

Fort Wayne as a Logistics Hub for Material Supply

Fort Wayne’s location — near I-69, I-469, and key rail lines — makes it a strategic distribution point for metals throughout the Midwest. When you work with a reliable aluminum coil supplier in Fort Wayne, Indiana, you can expect:

- Fast turnaround times for businesses in Indiana, Ohio, and Michigan

- Customized coil widths, tempers, and finishes for various industries

- Consistent inventory to avoid supply chain delays

Whether you’re sourcing aluminum for construction or production, local availability reduces downtime and improves project timelines.

How Aluminum Coil Improves Project Efficiency

Choosing aluminum coil allows fabricators to:

- Cut faster: Aluminum is easier to shear, slit, or stamp than heavier metals.

- Reduce labor costs: Lighter materials are easier to transport, lift, and manipulate.

- Improve final product weight: Especially critical for shipping, installation, or consumer handling.

These efficiencies make aluminum coil an integral part of streamlined fabrication workflows.

Why Partner with Randall Metals in Fort Wayne?

Manufacturers in Fort Wayne, Indiana benefit from working with suppliers who understand both technical specs and logistical needs. Randall Metals provides:

- Slit coils and custom-cut lengths

- Quality assurance for thickness, temper, and coating

- Regional delivery support and just-in-time shipments

With over 30 years of experience, Randall Metals remains a trusted source for aluminum coil supply across industrial sectors in Indiana and the Midwest.

Looking for an Aluminum Coil Supplier in Fort Wayne, Indiana?

Are you ready to partner with a dependable aluminum coil supplier in Fort Wayne, Indiana that can help streamline your next lightweight fabrication project? If so, Randall Metals is the top choice. Contact us today to learn how we can help.