Understanding the Advantages of Cold Rolled Steel in Precision Manufacturing – Insights from a Cold Rolled Steel Coil Supplier in Overland Park, Kansas

Cold rolled steel has become an essential material for manufacturers who require accuracy, consistency, and dependable strength. As production standards continue to rise, industries rely on materials that deliver reliable performance without variation. Cold rolling supports this need by refining steel through a controlled process that enhances surface quality, dimensional tolerance, and formability.

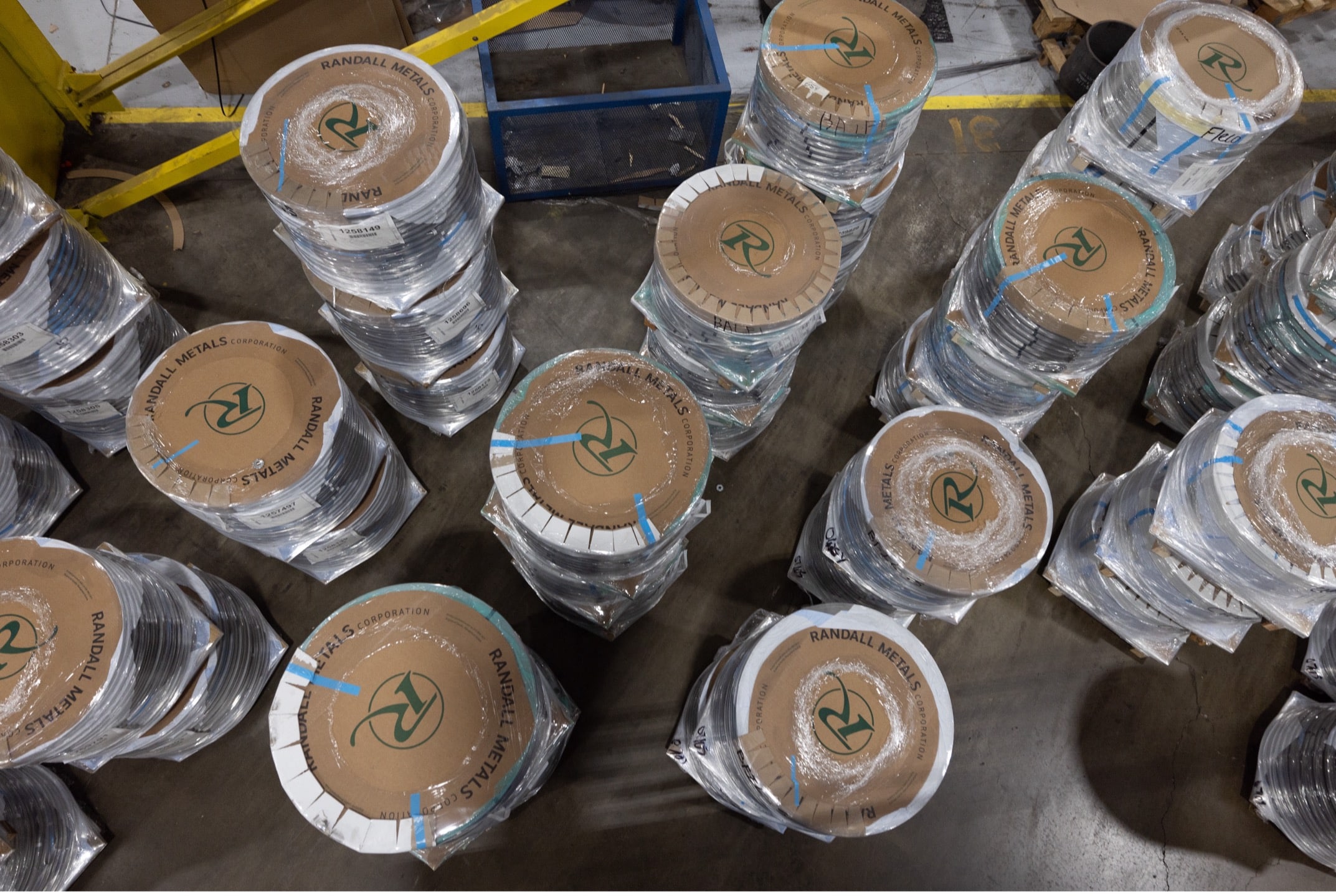

As the leading cold rolled steel coil supplier in Overland Park, Kansas, Randall Metals provides material that supports a wide range of precision manufacturing applications across the Midwest. Understanding how cold rolled steel is produced and why it is widely used helps explain its ongoing importance in precision manufacturing. Read below to find out how it works.

How the Cold Rolling Process Works

Cold rolling begins with hot rolled steel that has been cooled and descaled. The steel is then passed through rollers at room temperature, which compress the material and reduce its thickness. This controlled reduction refines the grain structure and produces a smoother surface with improved uniformity.

Because the steel is worked without heat, the process enhances strength through strain hardening and results in a product with excellent mechanical and dimensional consistency. These characteristics make cold rolled steel a dependable option for applications that require tight tolerances.

Supporting Midwest Manufacturing and Industrial Growth

Overland Park and the surrounding region support a diverse range of industries, including automotive, construction materials, metal fabrication, and appliance manufacturing. Cold rolled steel coil is used extensively across these sectors due to its versatility and consistent properties.

As the best cold rolled steel coil supplier in Overland Park, Kansas, Randall Metals provides material that meets performance expectations for both high-volume production and specialized fabrication work. Reliable supply supports manufacturing schedules and ensures projects continue without disruption.

The Role of Surface Finish in Production

A distinguishing feature of cold rolled steel is its clean, uniform surface. This smooth finish helps improve coating adhesion and reduces the amount of preparation needed before painting or other finishing processes.

Manufacturers who require a consistent surface appearance appreciate the level of refinement achieved through cold rolling. This characteristic supports industries that produce consumer-facing goods, fabrication components, and equipment housings.

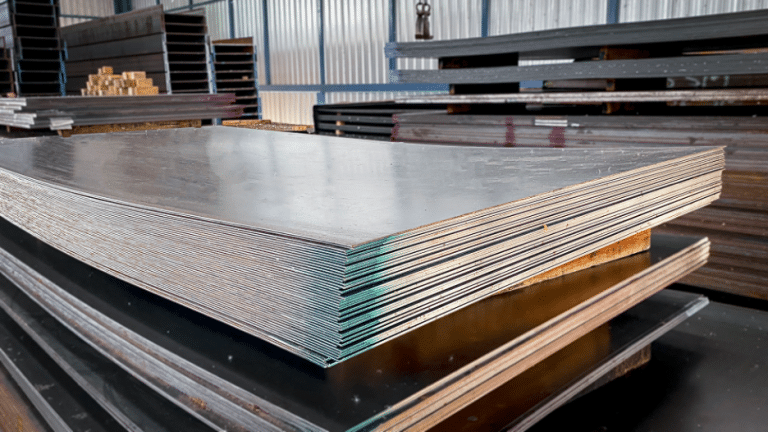

Dimensional Accuracy for Precision Fabrication

Cold rolled steel coil is known for its consistent thickness and tight dimensional tolerances. These characteristics allow fabricators and manufacturers to create components that fit together with precision, reducing errors during assembly or forming.

Dimensional accuracy is especially important for stamping, bending, or machining applications where material variation can impact part performance. Randall Metals supplies cold rolled steel with the uniformity needed to maintain consistent results across production cycles.

Formability and Structural Performance

Cold rolled steel combines strength with good formability, making it suitable for parts that require both structural integrity and detailed shaping. Manufacturers rely on these properties to create components that must withstand stress while maintaining specific geometries.

The material’s ability to hold shape during forming processes supports large-scale production as well as custom fabrication work. Its predictable performance helps engineers design components with confidence.

Supporting Efficiency in Manufacturing

Efficient production depends on materials that perform reliably. Cold rolled steel’s consistency reduces waste, minimizes rejected parts, and supports uninterrupted workflows. Reliable coil supply also allows manufacturers to plan more easily and maintain steady output.

When you partner with a full-service cold rolled steel coil supplier in Overland Park, Kansas — like Randall Metals — we’ll make sure you have the materials needed to stay on track with your production schedules.

Why Cold Rolled Steel Remains a Preferred Choice

Cold rolled steel continues to be widely used because it balances strength, precision, and surface quality. Its uniformity makes it suitable for industries that require detailed components, while its durability supports long-term performance.

Manufacturers across the Midwest rely on cold rolled steel to create parts, structures, and finished products that meet strict standards. Randall Metals supports these needs by providing material with dependable characteristics and consistent quality.

Looking for a Cold Rolled Steel Coil Supplier in Overland Park, Kansas?

At Randall Metals, we supply cold rolled steel coil that meets the needs of precision manufacturing, fabrication, and industrial production. As the most trusted cold rolled steel coil supplier in Overland Park, Kansas, you can count on us for consistent, high-quality materials. Contact us today to request a free quote.